Welcome to Fronhofer Tool, Inc.

Fronhofer Tool is a customer oriented machine shop / job shop located in beautiful Washington County, NY. Started in 1980, in the basement of his home, Paul Fronhofer started machining and doing business as Fronhofer Tool Company.

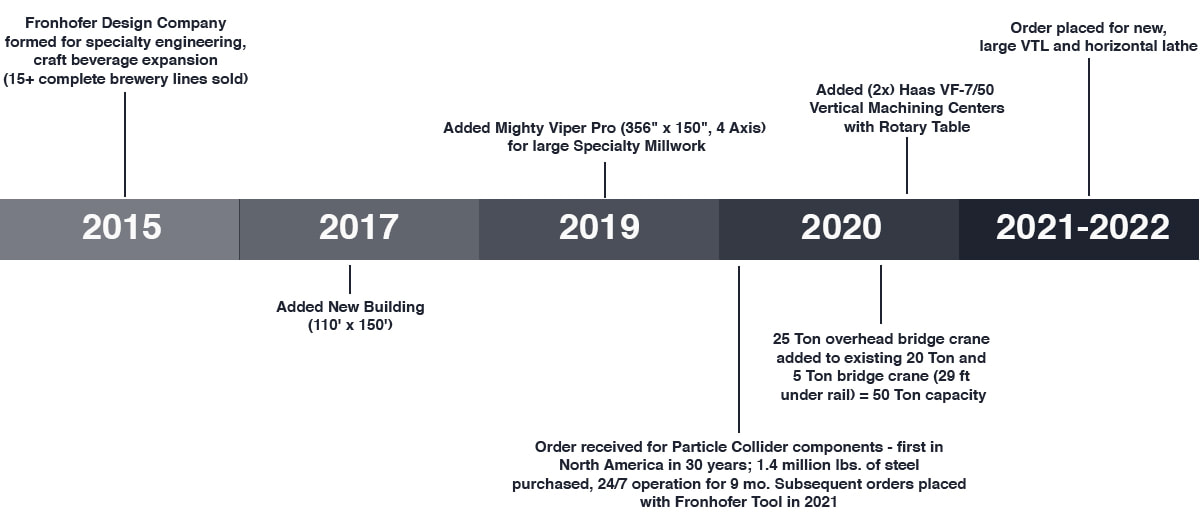

Today, after several major expansions, Fronhofer Tool Company includes a 60,000 sq.ft. manufacturing facility that specializes in the machining and fabrication of parts and components that range in size from the smallest locking pins to single 100,000 lb (50t) fabrications.

Our facilities are located in northeastern New York; approximately 45 minutes from Albany and 25 minutes to Glens Falls and Saratoga Springs. We deliver locally and ship both nationally and internationally.

Our facilities are located in northeastern New York; approximately 45 minutes from Albany and 25 minutes to Glens Falls and Saratoga Springs. We deliver locally and ship both nationally and internationally.

|

"

|

Success in business is no different than success in any other aspect of life. Whether it's sports, family, career or community, the ability to see opportunity and gain ground is more important than the ability to give back after the fact. Life has a balance and it's important that we all do our part to maintain it.

|

"

|

3 Generations of Machinists

First GenerationLeonard Fronhofer IIIBorn in December of 1924, the son of two German immigrants, Leonard Fronhofer III learned early that his interests were not in the bakery business that his father owned, but more in the mechanical field. By the time Leonard was a young teenager he had a collection of early model Fords. Repairing and rebuilding them became second nature and at times his collection of vehicles exceeded half a dozen and he kept them all in good running condition.

At the age of 14 or 15 he decided to build a tractor and using parts from model A’s and model T’s, his project began. Starting in the front he powered it with a Model A engine. After that came two Model A dump truck transmissions and a model T differential (worm gear type) in the rear. He made chains for the tires from used parts donated to him and cut angle iron pieces to bolt on to them for added traction. All this was done with very basic tools including a vise, a drill, and a hacksaw. Many hours went into the project but soon it came to a halt. He needed a metal lathe and had to purchase tires, which probably would have stopped the project had it not been for the good will of the school shop teacher. He let my father use their metal lathe and found a garage that would donate tires for his tractor. It was never my dads idea but the shop teacher took a real interest in the project and had the class paint it, even talked him into entering it at the Trenton Fair in New Jersey; my dad was only 15 or 16 at the time and won first prize. Perhaps being introduced to the use of that lathe and the interest that teacher took in my dad’s project are to be credited for the following three generations of machinists. Leonard went on to complete his apprenticeship and started his own small machine shop, which did repairs for local farmers. |

Second GenerationPaul Fronhofer - Fronhofer Tool Company Inc.

Carl Fronhofer & Socrates Fronhofer - BDP Industries (Belt Dewatering Press) Van Fronhofer - Val Industries Third GenerationPaul Fronhofer II - Fronhofer Tool Company Inc.

Kyle Fronhofer - Fronhofer Tool Company Inc. |